HASTELLOY B2 UNS N10665 W.NR.2.4617

Chemical Composition

|

Alloy |

element |

C |

Si |

Mn |

S |

P |

Ni |

Cr |

Mo |

Fe |

Co |

|

Alloy B2 |

Min |

26.0 |

|||||||||

|

Max |

0.02 |

0.10 |

1.00 |

0.03 |

0.04 |

Balance |

1.0 |

30.0 |

2.0 |

1.0 |

Mechanical Properties

|

Aolly Status |

Tensile strength Rm Mpa Min |

Yield strength R P 0. 2 Mpa Min |

Elongation A 5 % Min |

|

Solution |

745 |

325 |

40 |

Physical Properties

|

Density g/cm3 |

Melting Point ℃ |

|

9.2 |

1330~1380 |

Standard

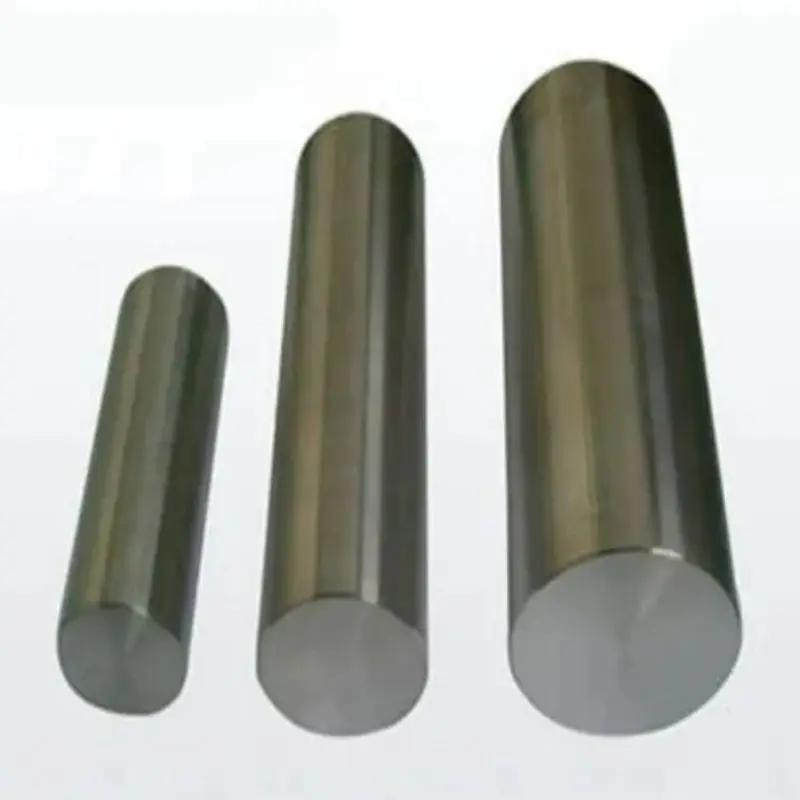

Rod, Bar, Wire and Forging Stock - ASTM B 335(Rod, Bar), ASTM B 564(Forging),ASTM B 366(Fitting)

Plate, Sheet and Strip - ASTM B 333

Pipe and Tube - ASTM B 622(Seamless ) ASTM B 619/B626(Welded Tube)

Characteristics of Hastelloy B2

● Great resistance to stress corrosion cracking and pitting

● Significant resistance to reducing conditions like hydrogen chloride, sulfuric,acetic and phosphoric acids

● Resistance to hydrochloric acid at all concentrations and temperatures

● Previous: INCONEL® alloy C-276 UNS N10276/W.Nr. 2.4819

● Next: HASTELLOY B-3 UNS N10675/W.Nr.2.4600

Why Choose Us:

1. Professional R&D team

Application test support ensures that you no longer worry about multiple test instruments.

2. Product marketing cooperation

The products are sold to many countries all over the world.

3. Strict quality control

4. Stable delivery time and reasonable order delivery time control.

We are a professional team, our members have many years of experience in international trade. We are a young team, full of inspiration and innovation. We are a dedicated team. We use qualified products to satisfy customers and win their trust. We are a team with dreams. Our common dream is to provide customers with the most reliable products and improve together. Trust us, win-win.